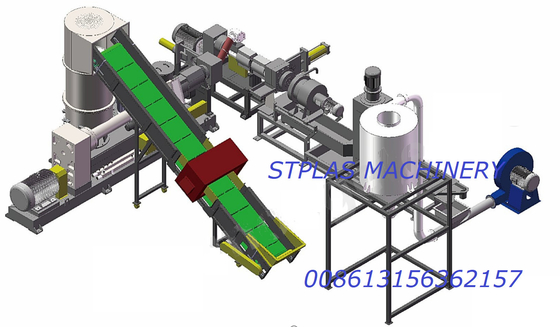

PE/PP Film Woven Bags Die-Face Cutting Pelletizing Line

We have two types of PE granulating line: one stage and two stags.

Waste Plastic PP PE Film/Jumbo Woven Bag/Raffia Recycling granulating machine is especially good for the raw material which contain high moisture, high impurities.

The first stage extruder adopts exhaust type barrel screw, which can effectively de-gassing and eliminate the moisture and

contamination; And the second extruder usually adopts small L/D extruder, further plasticizing the material and filter contamination which can achieve stable extrusion.

Which Kind raw material can be recycled?

Main Features

1) Single stage extruder and double stage extruders can be used according to user's requirement or material condition.

2) Plastic pelletized polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (pvc), PET, HDPE, ABS and other engineering plastics or general plastics recycling and granulation.

3) Granules cutting type: water ring face cutting, strip/noodle type cutting and hot cutting;

4) Waste woven bags and waste film can be directly put into the granulation line without crushing.

5) The main engine is equipped with full automatic control cabinet and PLC operating system. It is easy to operate and has stable performance.

6) Low energy consumption, remarkable energy saving effect, high output, mechatronics. Plastic granulation

SJ series plastic granulator

|

No

|

Machine Name

|

QTY(SET)

|

Remarks

|

|

1.

|

Belt Conveyor

|

1

|

|

|

2.

|

Compactor/Agglomerator

|

1

|

|

|

3.

|

Single screw Extruder

|

1

|

|

|

4.

|

Sub-Feeder (to make modified pellets)

|

1

|

Optional

|

|

5.

|

Screen changer

|

1

|

|

|

6.

|

Die head

|

1

|

|

|

7.

|

Water ring cutter

|

1

|

|

|

8.

|

Hydraulic station

|

1

|

|

|

9.

|

Vibrating screen Machine

|

1

|

|

|

10.

|

Dewatering machine

|

1

|

|

|

11.

|

Storage hopper

|

1

|

|

Technical parameters

SJ series double-stage pe pp film granulator machine(with side feeder)

| Model |

SJ-100/100 |

SJ-120/120 |

SJ-150/150 |

SJ-200/200 |

| Screw Dia. |

100 |

120 |

150 |

200 |

| L/D |

28-30

10-15

|

28-30

10-15

|

28-30

10-15

|

28-30

10-15

|

| Capacity |

120-180kg/h |

300kg/h |

400-500kg/h |

800-900kg/h

|

|

item

|

value

|

|

Condition

|

New

|

|

Place of Origin

|

China

|

|

|

Jiangsu

|

|

Brand Name

|

STPLAS

|

|

Plastic Type

|

PE, PP/PE, PP

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product 2020

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

|

|

Dimension(L*W*H)

|

2900*1400*2195 (l/w/h) mm

|

|

Certification

|

CE

|

|

Warranty

|

1 Year

|

|

After-sales Service Provided

|

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

|

|

Key Selling Points

|

Automatic

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

|

|

After Warranty Service

|

Video technical support, Online support, Spare parts, Field maintenance and repair service

|

|

Local Service Location

|

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Australia, Morocco, Kenya, South Korea, Colombia, Algeria, Sri Lanka, Romania, South Africa, Nigeria

|

|

Showroom Location

|

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Nigeria, Australia

|

|

Product name

|

Plastic Recycling Film Squeezing Pelletizing Granulator Extruder

|

|

Function

|

Solid Waste

|

|

Name

|

Plastic Recycling Equipment

|

|

Application

|

Plastis

|

|

Raw material

|

PP PE ABS PC PET

|

|

Plastic Type

|

PP PE Films Bags

|

|

Keyword

|

Pp Pe Plastic Granulating Machine

|

|

Material Processed

|

Extruder

|

|

Final product

|

Foam Blocks

|

|

Capacity

|

300-1000kg/h

|

Advantages

1) Suitalbe for plastic film PP ,PE ,HDPE,LDPE,LLDPE and so on.

2) Equipped with the vertical and horizontal force-feeding device to ensure high output.

3) Vent design on the barrel to evaporate the volatiles form the recyle material.

4) Hydraulic screen change unit and pressure gauge for easy operation and safety.

5) Water chamber with die face cutter simplifes the process.

6) The vertical centrifuge separates and dry the pellets faster.

7) High-efficient force-feeder ensures high capacity feeding, low energy consumption

8) Plastic pelletizer style: water-ring cutting with extrusion mould, even cutting ensures good shape.